Sourcing bamboo sounds romantic, doesn’t it? A noble artist wandering through misty groves, selecting the perfect stalk like a samurai choosing his blade. In reality? Try sweat, machete blisters, and an ongoing fear that of the Green Tree Snake, a small beast who’s favoured method of attack is to hide in trees and nip unwary passers by.

Let me rewind.

I needed bamboo—strong, straight, seasoned bamboo—for a construction project that I was overly optimistic about. I told myself: “How hard can it be? It’s grass!”

Turns out, sourcing good bamboo is an emotional journey somewhere between treasure hunt and tragicomedy.

First, I tried sourcing from the wild. I hacked my way into a bamboo clump on my brother’s land, armed with a rusty machete and a can-do attitude. After much choppery one actually fell into a ditch, and I returned to my workstation victorious … and the poles promptly cracked because I forgot about curing.

Next, I tried the local builder’s merchant. Bamboo is used as scaffolding here, and they sell 4 metre poles by the ten-pack. I bundled one onto the back of the pickup and set off. Actually these poles served me well – I’d go on to buy many of them.

But these poles have very thin walls – a consequence of their youth – and so they crack when under load. Having said that, they are super flexible and great for things like splits and weaving, where heavier bamboos just simply don’t move.

But after a few failed construction concept models it was obvious – I just didn’t know enough about my bamboos.

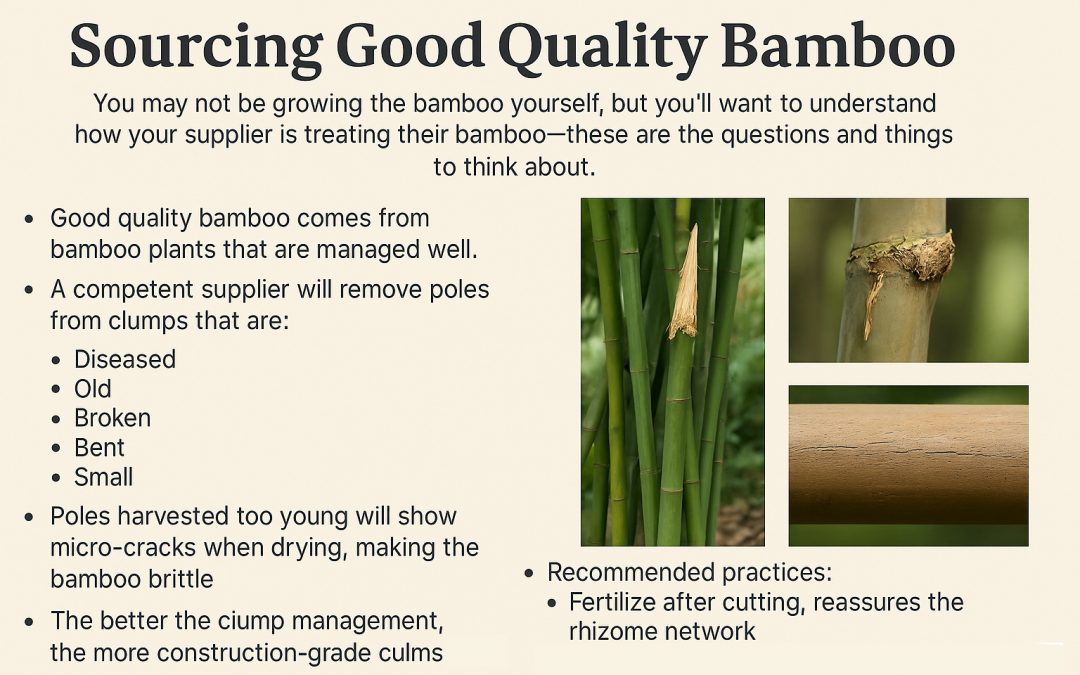

So it was over to an extensive period with Mr Google and Mr ChatGPT. I was introduced me to the concept of 5-year-old culms (at this age lignite thickness so poles become more woody – i.e. less prone to crack), proper harvesting cycles (don’t get too high from your own supply), and—get this—borax. Not for cleaning toilets. For treating bamboo. Who knew?

Look for a greyish patina (signifying age), the dry hollow knock (signifying woodiness), and the telltale curve of a culm that’s lived a life and won’t twist at the first sign of rain.

Suddenly, I wasn’t just building with bamboo. I was wallowing in bamboo.

And then there was that guy. Let’s call him Mr. Friendly. I went up to visit him in nearby Phuket; charming smile, firm handshake, promised me “only the best bamboo.” I liked him instantly. So I handed over $500 for about 100 poles, thinking I’d struck a bargain.

A few days later, he rolled up in a truck that sounded like it was held together by prayer and duct tape. He unloaded the poles at speed, declined my offer of tea (a red flag, in hindsight), and vanished like a bamboo-based magician.

At first glance, the poles looked fine. But over the following weeks as I started to use the poles, the truth crept in like rising damp. Cracks. Everywhere. Hairline at first, then yawning like mouths mid-yawn. They’d clearly been sitting in the sun, soaked in the rain, and possibly used to prop up a collapsing barn before making their way to me. My WhatsApp messages to Mr. Friendly went unanswered—ghosted by a man with a pickup and poor-quality grass.

That’s when I learned: serious suppliers use contracts. Actual, written contracts. They specify number of cracks, age, moisture content. Apparently, this is a thing. Who knew? I do now.

What I Learned

- Age matters – 3–5 years is the sweet spot.

- Cut in the dry season – unless you like fungus.

- Cure it properly – air-drying is an art.

- Treatment isn’t optional – unless you want termites to make friends.

- And yes, you will overpay for bad poles before finding the good stuff.

But once you do… oh, the joy. You find a culm that’s straight, smooth, golden as old teak, and you whisper to it, “You and me, we’re making something beautiful.”

And somehow, you both believe it.